05

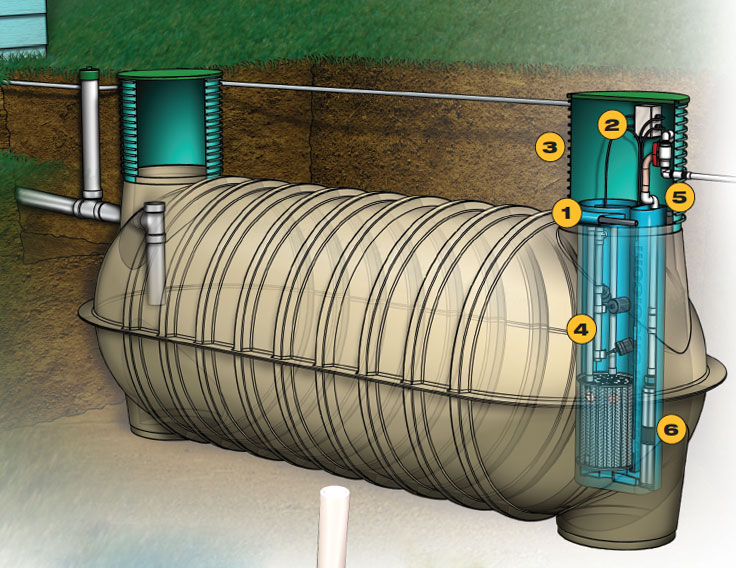

A lift station is a crucial part of many wastewater management systems, particularly in areas where gravity alone is insufficient to transport sewage or wastewater to the treatment facility. Lift stations are essential in both residential and commercial septic systems, playing a vital role in ensuring that wastewater is effectively moved from lower to higher elevations. Whether you are considering a septic tank installation or need advice on septic tank repair, understanding the components of a lift station can be incredibly valuable.

The wet well is essentially a storage basin where the wastewater accumulates. This is the first stop in the lift station where sewage and wastewater are collected before being pumped out. The wet well is designed to hold a specific amount of wastewater, preventing overflow and allowing the system to handle varying levels of incoming flow.

Maintenance Tip: Regular septic tank pumping and wet well cleaning are essential to prevent solids from accumulating and causing blockages or pump failures.

The pumps are the heart of the lift station. Depending on the system's design, there may be one or more pumps, which are responsible for moving the wastewater out of the wet well and into the sewer system or treatment facility. These pumps are typically submersible and are designed to handle the tough, corrosive environment found in lift stations.

The control panel is the brain of the lift station, managing the operation of the pumps based on the levels of wastewater in the wet well. It includes components like level sensors, alarms, and switches that automate the system’s operation. The control panel ensures that the pumps start and stop at the correct times, preventing both overflow and dry running.

Valves are essential for controlling the flow of wastewater within the lift station. They ensure that the flow is directed correctly and prevent backflow, which can cause system failure or contamination.

The piping within a lift station connects all the components, guiding the wastewater from the wet well to the pumps and eventually out to the sewer system or treatment plant. The pipes must be durable and corrosion-resistant to handle the harsh environment of a lift station.

Maintenance Tip: Regular inspection of the piping for leaks, cracks, or corrosion can prevent more serious issues that might require extensive septic tank repair.

Understanding the components of a lift station is crucial for anyone involved in septic tank installation, maintenance, or repair. Whether you're installing a new system or maintaining an existing one, staying informed about the key elements of a lift station will help you keep your wastewater management system in top condition. Be sure to contact Charlotte Septic Pros when you’re in need of quality plumbing services.

04

Early Warning Signs Your Septic Tank Needs Pumping For homeowners who rely on a septic system, routine maintenance is not…

Read more

29

Why Does My Septic System Smell Fine One Day and Terrible the Next? If you own a home with a…

Read more

19

Is Your Septic System Overdue? Simple Home Checks You Can Do Today For many homeowners, the septic system is a…

Read more

13

5 Signs Your Septic Tank Is Overdue for Pumping Your septic system works quietly behind the scenes, managing wastewater from…

Read more

07

Do Septic Additives Really Work? Septic additives are everywhere. You’ll see them at hardware stores, advertised online, and often recommended…

Read more

29

5 Things You’re Doing Every Day That Fill Up Your Septic Tank Faster Your septic system works quietly in the…

Read more

21

Is It Normal for Grass to Grow Greener Over My Septic Tank? If you’ve noticed a patch of grass in…

Read more

16

Why You Shouldn’t Wait Too Long to Pump Your Septic Tank A septic system works tirelessly behind the scenes to…

Read more

07

Septic Tank Smells? Let’s Talk About What’s Really Going on Underground A septic system is designed to manage wastewater efficiently…

Read more

31

Why Neglecting Your Septic Tank Can Affect Your Yard, Home, and Health A well-functioning septic system is essential for managing…

Read more